Ngikholwa ukuthi wonke umuntu uzwileirobhothi. Ivamise ukubonisa amandla ayo kumamuvi, noma iyindoda yesandla sokudla ye-Iron Man, noma isebenzise ngokunembile amathuluzi ahlukahlukene ayinkimbinkimbi ezimbonini zobuchwepheshe obunembayo. Lezi zethulo eziqanjiwe zisinika umbono wokuqala kanye nelukuluku mayelanairobhothi. Ngakho-ke yini irobhothi elikhiqiza izimboni?

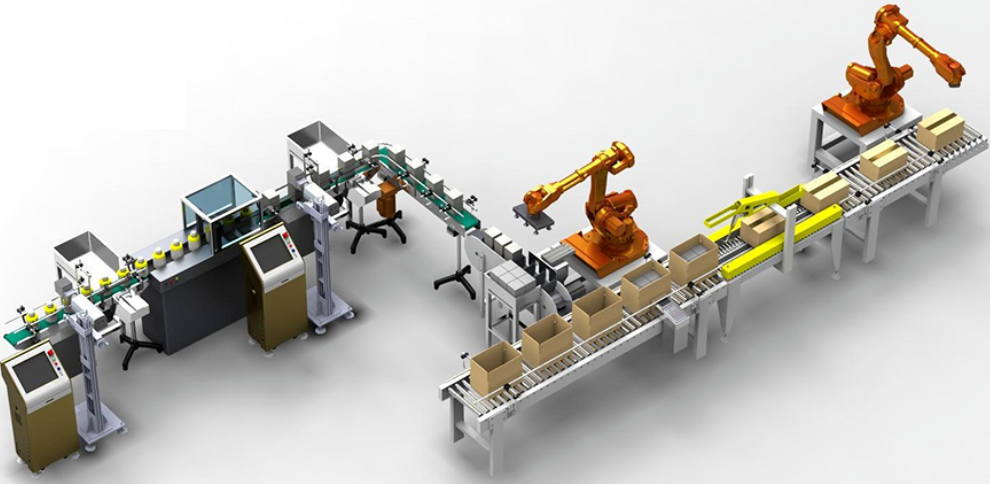

Anirobhothi lokukhiqiza izimboniiyisisetshenziswa esiwumshini esikwazi ukwenza imisebenzi ngokuzenzakalelayo. Ingakwazi ukulingisa okunye ukunyakaza kwezingalo zomuntu futhi yenze imisebenzi efana nokubamba impahla, ukucubungula izingxenye, nokuhlanganisa umkhiqizo endaweni yokukhiqiza yezimboni. Isibonelo, endaweni yokusebenzela yokukhiqiza izimoto, irobhothi lingakwazi ukubamba izingxenye zemoto ngokunembile futhi lizifake endaweni ecacisiwe. Amarobhothi akhiqiza izimboni ngokuvamile anikwa amandla ngamadivayisi okushayela afana namamotho, amasilinda, namasilinda amanzi. Lawa madivaysi okushayela ahambisa amalunga erobhothi ngaphansi komyalo wesistimu yokulawula. Isistimu yokulawula yakhiwe ngokuyinhloko isilawuli, inzwa, kanye nedivayisi yokuhlela. Isilawuli “ubuchopho” berobhothi, obuthola futhi bucubungule imiyalelo namasiginali ahlukahlukene. Inzwa isetshenziselwa ukuthola indawo, isivinini, amandla, nolunye ulwazi lwesimo serobhothi. Isibonelo, phakathi nenqubo yokuhlanganisa, inzwa yamandla isetshenziselwa ukulawula amandla okuhlanganisa ukugwema ukulimala ezingxenyeni. Idivayisi yokuhlela ingaba umhleli wokufundisa noma isofthiwe yokuhlela ikhompuyutha, futhi i-trajectory yokunyakaza, ukulandelana kwesenzo kanye nemingcele yokusebenza ye-manipulator ingasethwa ngohlelo. Isibonelo, emisebenzini yokushisela, indlela yokunyakaza kanye nemingcele ye-welding yekhanda le-welding ye-manipulator, njengejubane lokushisela, usayizi wamanje, njll., ingasethwa ngohlelo.

Izici ezisebenzayo:

Ukunemba okuphezulu: Ingakwazi ukubeka ngokunembile futhi isebenze, futhi iphutha lingalawulwa ezingeni lemilimitha noma ngisho neleveli ye-micron. Isibonelo, ekukhiqizeni amathuluzi anembayo, isikhohlisi singahlanganisa ngokunembile futhi sicubungule izingxenye.

Isivinini esikhulu: Ingakwazi ukuqedela ngokushesha izenzo eziphindaphindayo futhi ithuthukise ukusebenza kahle kokukhiqiza. Isibonelo, kulayini wokukhiqiza wokupakisha ozenzakalelayo, isikhohlisi singathatha ngokushesha imikhiqizo futhi siyifake ezitsheni zokupakisha.

Ukuthembeka okuphezulu: Kungasebenza ngokuzinza isikhathi eside futhi kunciphise amaphutha abangelwa izici ezifana nokukhathala nemizwa. Uma kuqhathaniswa nomsebenzi wezandla, kwezinye izindawo zokusebenza ezinokhahlo, njengezinga lokushisa eliphezulu, ubuthi, nomfutho ophakeme, isikhohlisi singasebenza ngokuqhubekayo.

Ukuvumelana nezimo: Imisebenzi yayo yokusebenza kanye nezindlela zokunyakaza zingashintshwa ngohlelo ukuze livumelane nezidingo ezahlukene zokukhiqiza. Isibonelo, i-manipulator efanayo ingakwazi ukuphatha izinto ezihamba ngesivinini esiphezulu ngesizini yokukhiqiza ephezulu kanye nokuhlanganisa imikhiqizo emihle ngesikhathi esingekho.

Yiziphi izindawo zokusetshenziswa kwama-manipulators okukhiqiza izimboni?

Imboni Yokukhiqiza Izimoto

Ukuphatha Izingxenye kanye Nokuhlanganisa: Emigqeni yokukhiqiza izimoto, amarobhothi angakwazi ukuthwala kahle izingxenye ezinkulu njengezinjini nama-transmissions futhi azihlanganisele ngokunembile ku-chassis yemoto. Isibonelo, irobhothi elinama-eksisi ayisithupha lingafaka isihlalo semoto endaweni ethile emzimbeni wemoto ngokunemba okuphezulu kakhulu, futhi ukunemba kokuma kwalo kungafinyelela ku-±0.1mm, kuthuthukisa kakhulu ukusebenza kahle komhlangano kanye nekhwalithi. I-Welding Operation: Umsebenzi wokushisela womzimba wemoto udinga ukunemba okuphezulu nesivinini. Irobhothi lingakwazi ukushisela izingxenye ezihlukahlukene zohlaka lomzimba ndawonye lisebenzisa ubuchwepheshe bokushisela amabala noma i-arc ngendlela ehlelwe kusengaphambili. Isibonelo, irobhothi elikhiqizayo lemboni lingaqedela ukushiselwa kohlaka lomnyango wemoto emizuzwini engu-1-2.

Imboni kagesi kanye nekagesi

Ukwenziwa Kwebhodi Lesifunda: Ngesikhathi sokukhiqizwa kwamabhodi esekethe, amarobhothi angakwazi ukukhweza izingxenye ze-elekthronikhi. Ingakwazi ukukhweza ngokunembile izingxenye ezincane ezinjengama-resistors nama-capacitor kumabhodi wesifunda ngesivinini sezingxenye ezimbalwa noma inqwaba yezingxenye ngomzuzwana. Umhlangano Womkhiqizo: Ngokuhlanganiswa kwemikhiqizo ye-elekthronikhi, efana nomakhalekhukhwini namakhompyutha, amarobhothi angaqedela imisebenzi efana nokuhlanganisa igobolondo nokufakwa kwesikrini. Uma sithatha ukuhlanganiswa kwefoni ephathekayo njengesibonelo, irobhothi lingafaka ngokunembile izingxenye ezifana nezikrini zokubonisa namakhamera emzimbeni wefoni ephathekayo, iqinisekise ukuvumelana kanye nekhwalithi ephezulu yokuhlanganisa umkhiqizo.

Imboni yokucubungula imishini

Imisebenzi yokulayisha nokukhipha: Phambi kwamathuluzi omshini we-CNC, imishini yokugxiviza nezinye izinto zokucubungula, irobhothi lingenza umsebenzi wokulayisha nokukhipha. Ingakwazi ukusheshe ibambe impahla engenalutho esiseleni bese iyithumela endaweni yokusebenza yemishini yokucubungula, bese ikhipha umkhiqizo osuphelile noma umkhiqizo osuphelile ngemva kokucubungula. Isibonelo, lapho i-CNC lathe icubungula izingxenye ze-shaft, irobhothi lingaqedela umsebenzi wokulayisha nokulayisha njalo ngamasekhondi angu-30-40, okuthuthukisa izinga lokusetshenziswa kwethuluzi lomshini. Usizo lokucubungula ingxenye: Ekucutshungulweni kwezingxenye ezithile eziyinkimbinkimbi, irobhothi lingasiza ekuphenyeni nasekumiseni izingxenye. Isibonelo, lapho icubungula isikhunta esiyinkimbinkimbi esinobuso obuningi, irobhothi lingakwazi ukuphendulela isikhunta endaweni efanele ngemva kokuba inqubo eyodwa isiqediwe ukuze ilungiselele inqubo elandelayo, ngaleyo ndlela ithuthukise ukusebenza kahle nokunemba kwengxenye yokucubungula.

Imboni yokudla neziphuzo

Imisebenzi yokupakisha: Kusixhumanisi sokupakisha sokudla neziphuzo, irobhothi lingabamba umkhiqizo liwufake ebhokisini lokupakisha noma esikhwameni sokupakisha. Isibonelo, emugqeni wokukhiqiza isiphuzo, irobhothi lingabamba futhi lipakishe amabhodlela eziphuzo angama-60-80 ngomzuzu, futhi lingaqinisekisa ukuhlanzeka kanye nokumiswa kwephakheji.

Umsebenzi wokuhlunga: Ukuze kuhlelwe ukudla, njengokuhlela nokuhlukanisa izithelo nemifino, irobhothi lingakwazi ukuhlunga kuye ngobukhulu, isisindo, umbala nezinye izici zomkhiqizo. Enqubweni yokuhlunga ngemva kokuvunwa kwesithelo, irobhothi lingakwazi ukubona izithelo zekhwalithi ehlukene futhi lizibeke ezindaweni ezihlukene, okuthuthukisa ukusebenza kahle kokuhlunga kanye nekhwalithi yomkhiqizo.

Logistics kanye warehousing industry

Ukuphathwa kwempahla kanye ne-palletizing: Endlini yokugcina impahla, irobhothi lingathwala izimpahla zomumo nezisindo ezihlukahlukene. Ingase ikhiphe izimpahla emashalofini noma ibeke izimpahla kuma-pallet. Isibonelo, amarobhothi amakhulu ezinto kanye namarobhothi agcina impahla angathwala izimpahla ezinesisindo esingamathani amaningana, futhi angapakisha izimpahla zibe izitaki ezihlanzekile ngokwemithetho ethile, okuthuthukisa ukusetshenziswa kwendawo yokugcina impahla. Ukuhlunga ama-oda: Ezimweni ezifana ne-e-commerce logistics, irobhothi lingakwazi ukuhlunga izimpahla ezihambisanayo kumashalofu e-warehouse ngokolwazi lwe-oda. Ingakwazi ukuskena ngokushesha ulwazi lomkhiqizo futhi ibeke ngokunembile imikhiqizo ebhandeni lokuthutha lokuhlunga, isheshise ukucutshungulwa kwe-oda.

Yimiphi imiphumela ethile yokusetshenziswa kwezikhohlisi zokukhiqiza izimboni ekusebenzeni kahle kokukhiqizwa kwebhizinisi?

Thuthukisa isivinini sokukhiqiza

Ukusebenza okuphindaphindiwe okusheshayo: Izikhohlisi zokukhiqiza izimboni zingenza umsebenzi ophindaphindayo ngesivinini esiphezulu kakhulu ngaphandle kokukhathala kanye nokunciphisa ukusebenza kahle njengokusebenza mathupha. Isibonelo, enqubweni yokuhlanganisa izingxenye ze-elekthronikhi, isikhohlisi singaqedela inqwaba noma amakhulu ezenzo zokubamba nokufaka ngomzuzu, kuyilapho ukusebenza okwenziwa ngesandla kungase kuqedwe izikhathi ezimbalwa ngomzuzu. Ukuthatha ukukhiqizwa kwefoni ephathekayo njengesibonelo, inombolo yezikrini ezifakwe ngehora kusetshenziswa ama-manipulators ingaba izikhathi ezingu-3-5 ngaphezu kokufakwa ngesandla. Nciphisa umjikelezo wokukhiqiza: Njengoba i-manipulator ingasebenza amahora angu-24 ngosuku (ngokunakekelwa okufanele) futhi inesivinini sokuguqula esisheshayo phakathi kwezinqubo, ifinyeza kakhulu umjikelezo wokukhiqiza womkhiqizo. Isibonelo, ekukhiqizeni izimoto, ukusebenza kahle kwe-manipulator ku-welding yomzimba kanye nezixhumanisi zokuhlanganisa izingxenye kwehlise isikhathi sokuhlanganisa semoto sisuka emazingeni amaningi saya emahoreni angaphezu kwayishumi manje.

Thuthukisa ikhwalithi yomkhiqizo

Ukusebenza okunembayo okuphezulu: Ukunemba kokusebenza kwe-manipulator kuphezulu kakhulu kunokusebenza okwenziwa ngesandla. Ekwenziweni kwemishini okunembayo, irobhothi lingakwazi ukulawula ukunemba komshini kwezingxenye ukuya kuleveli ye-micron, okunzima ukuyifinyelela ngokusebenza okwenziwa ngesandla. Isibonelo, ekukhiqizeni izingxenye zewashi, irobhothi lingakwazi ukuqedela ngokunembile ukusika nokugaya izingxenye ezincane ezifana namagiya, liqinisekise ukunemba kobukhulu kanye nokuqedwa kobuso bezingxenye, ngaleyo ndlela lithuthukise ikhwalithi iyonke yomkhiqizo.

Ukuzinza kwekhwalithi enhle: Ukungaguquguquki kwayo kwesenzo kuhle, futhi ikhwalithi yomkhiqizo ngeke iguquguquke ngenxa yezinto ezifana nemizwa nokukhathala. Enqubweni yokupakisha izidakamizwa, irobhothi lingakwazi ukulawula ngokunembile umthamo womuthi kanye nokuvalwa kwephakheji, futhi ikhwalithi yephakheji ngayinye ingashintshashintsha kakhulu, yehlise izinga elingalungile. Isibonelo, ekufakweni kokudla, ngemva kokusebenzisa irobhothi, izinga lokulahlekelwa komkhiqizo elibangelwa ukupakishwa okungafanelekile lingancishiswa lisuka ku-5% - 10% ekusebenzeni ngesandla kuya ku-1% - 3%.

Lungiselela inqubo yokukhiqiza

Ukuhlanganiswa kwenqubo ezenzakalelayo: Irobhothi lingakwazi ukuxhuma kalula nezinye izinto zokusebenza ezizenzakalelayo (njengemigqa yokukhiqiza ezenzakalelayo, amasistimu okugcina impahla azenzakalelayo, njll.) ukuze lenze ngokugcwele yonke inqubo yokukhiqiza. Emgqeni wokukhiqiza wemikhiqizo ye-elekthronikhi, irobhothi lingahlanganisa eduze ukukhiqizwa, ukuhlolwa kanye nokuhlanganiswa kwamabhodi wesekethe ukuze kuzuzwe ukukhiqizwa okuqhubekayo okuzenzakalelayo kusuka ezintweni ezingavuthiwe kuya emikhiqizweni ephelile. Isibonelo, ku-workshop ephelele yokukhiqiza i-motherboard yekhompiyutha, irobhothi lingaxhumanisa imishini yokucubungula ehlukahlukene ukuze iqedele uchungechunge lwezinqubo kusukela ekukhiqizeni amabhodi wesifunda aphrintiwe kuya ekufakweni kwe-chip kanye nokushisela, ukunciphisa isikhathi sokulinda nokungenelela komuntu kuzixhumanisi eziphakathi. Ukulungiswa komsebenzi ovumelana nezimo: Imisebenzi yomsebenzi werobhothi nokuhleleka komsebenzi kungalungiswa kalula ngohlelo ukuze livumelane nezidingo ezahlukene zokukhiqiza kanye nezinguquko zomkhiqizo. Ekukhiqizeni izingubo, lapho isitayela sishintsha, uhlelo lwe-robot kuphela oludinga ukuguqulwa ukuze luvumelane nokusika, usizo lokuthunga kanye neminye imisebenzi yesitayela esisha sezingubo, okuthuthukisa ukuguquguquka nokuvumelana nezimo zesistimu yokukhiqiza.

Yehlisa izindleko zokukhiqiza

Yehlisa izindleko zabasebenzi: Nakuba ukutshalwa kwezimali kokuqala kwerobhothi kuphezulu, ngokuhamba kwesikhathi, kungashintsha inani elikhulu lomsebenzi wezandla futhi kunciphise izindleko zenkampani zabasebenzi. Isibonelo, inkampani eyenza amathoyizi esebenza kanzima inganciphisa u-50% -70% wabasebenzi bomhlangano ngemva kokwethula amarobhothi okuhlanganiswa kwezingxenye ezithile, ngaleyo ndlela yonge imali eningi ezindlekweni zabasebenzi. Yehlisa izinga le-scrap kanye nokulahlekelwa kwezinto ezibonakalayo: Ngenxa yokuthi irobhothi lingasebenza ngokunembile, linciphisa ukukhiqizwa kwe-scrap okubangelwa amaphutha okusebenza, futhi linciphisa nokulahlekelwa kwezinto ezibonakalayo. Phakathi nenqubo yokucosha nokuphungula imikhiqizo ebunjiwe yomjovo, irobhothi lingakwazi ukubamba imikhiqizo ngokunembile ukuze ligweme ukulimala komkhiqizo nokumosha izinsalela ngokweqile, lehlise izinga le-scrap ngo-30% - 50% kanye nokulahlekelwa kwempahla ngo-20% - 40%.

Isikhathi sokuthumela: Jan-21-2025