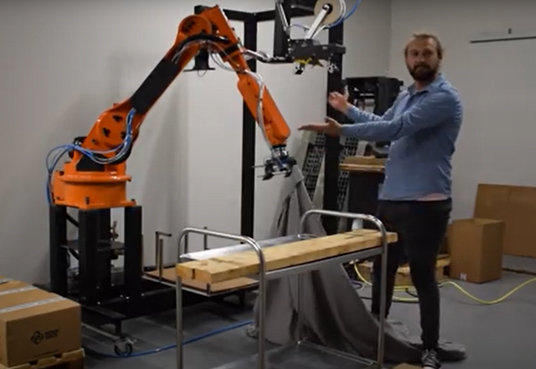

Iphakhejiirobhothiiyimishini ethuthukisiwe, ehlakaniphile, futhi ezenzakalela kakhulu, ehlanganisa ikakhulukazi amasistimu okubona ahlakaniphile, ama-manipulators okupakisha, ama-manipulators okuphatha, amasistimu wokupakisha kanye nezinhlelo zokulawula, njll. Ingena esikhundleni semisebenzi yezandla evamile futhi ibona izixhumanisi eziningi ezifana nokuthuthwa komkhiqizo, ukuhlunga, ukutholwa, ukupakisha, ukulayisha nokuthulula. Inezinzuzo zokusebenza kahle okuphezulu nokusebenza okunembile, okungasindisa ngempumelelo abasebenzi, isikhathi nezinye izindleko, futhi isetshenziswe kabanzi embonini yokudla. Ukuhlukaniswa kweamarobhothi okupakisha

Ukupakishwa komkhiqizo ngokuvamile kunezinhlobo eziningi. Ngokusho kokuma, izinto ezibonakalayo, isisindo kanye nezidingo zokuhlanzeka zento, inqubo yokupakisha iyinkimbinkimbi. Njengamanje, kunezinhlobo ezilandelayo zamarobhothi zale nqubo yokupakisha:

Irobhothi elithwala izikhwama: Irobhothi eliphethe izikhwama liwuhlobo lwe-rotary olungashintshi olunomzimba wokuzungezisa ongu-360-degree. Irobhothi liqedela ukuthutha, ukuvulwa kwesikhwama, ukulinganisa, ukugcwalisa, ukuthunga izikhwama nokupakisha isikhwama sokupakisha. Leli irobhothi lokupakisha elihlakaniphe kakhulu. Irobhothi lesibhakela: Ngokufana nerobhothi elithwalayo, isibhakela seziqukathi zokupakisha zensimbi nezengilazi ngokuvamile siqedwa irobhothi eliyibhokisi eliqinile. Kunezinhlobo ezimbili zezinhlobo zokudonsa ngomshini kanye nezomoya zokubamba amaphakheji asebhokisini. Iyakwazi ukunyakaza iyonke. Thatha noma khangisa iphakheji, bese ulithumela ebhokisini lokupakisha noma i-pallet endaweni eqokiwe. Inomsebenzi wokuqondisa okuzenzakalelayo kanye nokulungiswa kwesikhundla, futhi ayikwazi ukubona ukulayishwa nokulungiswa kwesiqondiso ngaphandle kwebhokisi (pallet). Lolu hlobo lwerobhothi iyirobhothi eselivuthiwe elinezinhlobonhlobo zezinhlelo zokusebenza. Okufana neziphuzo, ubhiya, njll.

Irobhothi eligcwalisayo: Leli irobhothi elikala, amakepisi, elicindezela (izikulufu) futhi likhombe ngemuva kokuthi isiqukathi sokupakisha sigcwaliswe ngezinto eziwuketshezi. Inemisebenzi yokungadli ngaphandle kwamabhodlela, akukho ukuphakela ngaphandle kwamakepisi, i-alamu yebhodlela ephukile kanye nokwenqatshwa okuzenzakalelayo. Esikhathini esidlule, izinto zethu eziningi eziwuketshezi zazigcwele ikakhulukazi umsebenzi wendawo waleli robhothi-i-manipulator yafakwa emgqeni wokukhiqiza. Manje, leli robhothi licushwe ngokuqondile ngemuva komsingathi wokukhiqiza izinto ezibonakalayo ukuze libone ukugcwaliswa kwalo okuzenzakalelayo. Amarobhothi okugcwalisa ahlukaniswe amaphakheji athambile kanye nokupakisha kanzima. Irobhothi lokugcwalisa eliqinile (elifaka ibhodlela) liyahlaziywa lapha.

Irobhothi elidlulisa ukupakisha: Lolu hlobo lwerobhothi embonini yokupakisha ikakhulukazi libhekise irobhothi elisetshenziselwa ukupakisha nokudlulisa amabhodlela epulasitiki. Isebenzisa amandla kanye nezingxenye ezikhethekile ukubona ukuhanjiswa kwamabhodlela (amabhodlela angenalutho), ikhipha ngokushesha futhi ihlele amabhodlela okupakisha emgqonyeni webhodlela, bese inika amandla athile (isiqondiso, usayizi). Yenza umzimba webhodlela udlule ngokunembile umzila we-parabola emoyeni ukuze ufinyelele umsebenzi wokugcwalisa. Leli robhothi lishintsha indlela evamile yokudlulisa ibhodlela. Isheshisa isivinini sokudlulisa futhi kunciphisa isikhala sokudlulisa. Kuyirobhothi elipakishayo elinomqondo omusha. Isebenzisa i-aerodynamics kanye nezingxenye ezikhethekile zemishini ukufeza ukusebenza kwayo kokudlulisa.

Izinzuzo zokupakisha amarobhothi

1. Ukunemba kokukhiqiza Ingalo yerobhothi ifakwe ngokuqinile kusisekelo somshini oqinile, futhi izimbazo zerobhothi ezinama-axis amaningi zizungeziswa ama-servo motors namagiya, okuqinisekisa ukuthi irobhothi lingakwazi ukunquma ngokuguquguqukayo nangokukhululekile indawo yokusebenza ngaphakathi kwendawo yokusebenza.

2. Ukusebenza kalula Uhlelo lulawula irobhothi, i-mechanical gripper kanye nebhande lokuthutha nge-PLC, futhi uhlelo lufakwe isikrini sokuthinta esikhethekile ukuze sibonise ulwazi phakathi nenqubo yokukhiqiza. Uhlelo lwamukela isixhumi esibonakalayo esithuthukisiwe somshini womuntu, futhi opharetha bangakwazi ukulungisa amapharamitha kalula futhi bakhethe izinhlelo kusixhumi esibonakalayo.

3. Ukuguquguquka kokukhiqiza I-gripper yerobhothi ifakwe phakathi nendawo ye-flange. Ingaklanywa njengethuluzi eligxilile noma ishintshwe izibambi ezichwepheshile ezihlukene ngomshini ozenzakalelayo oshintshayo ukuze uvumelane nemisebenzi ekhethekile. Irobhothi lingashintsha futhi lifake ama-grippers ahlukene ngokwezidingo zenqubo yokukhiqiza yangempela ukuze lihlangabezane nezidingo zokukhiqiza eziguquguqukayo. Irobhothi lingakwazi futhi ukusebenzisana nesistimu yokuhlola i-laser ukuze likhombe uhlobo lwesiqeshana sokusebenza futhi lisize irobhothi ukuthi lithole indawo yokusebenza.

Izici zokupakisha amarobhothi

1. Ukusebenza okuqinile: Uma usayizi, umthamo, ukwakheka kanye nobukhulu bangaphandle bemikhiqizo ekhiqizwe ibhizinisi kushintsha, kudingeka ukuguqulwa okuncane kuphela esikrinini esithintwayo, okungeke kuthinte ukukhiqizwa okuvamile kwebhizinisi. Ukushintsha ama-palletizer emishini yendabuko kunzima noma akunakwenzeka. 2. Ukuthembeka okuphezulu: I-robot yokupakisha ingahlala igcina isimo esifanayo ngesikhathi sokusebenza okuphindaphindiwe, futhi ngeke kube khona ukuphazamiseka okuzimele okufana nalokho kwabantu, ngakho-ke ukwethembeka kokusebenza kwalo kuphakeme kakhulu.

3. Izinga eliphakeme lokuzenzakalela: Ukusebenza kwerobhothi lokupakisha kuncike ekulawuleni uhlelo, ngaphandle kokubamba iqhaza komuntu, ngezinga eliphezulu lokuzishintshanisa, konga umsebenzi omningi.

4. Ukunemba okuhle: Ukulawulwa kokusebenza kwerobhothi lokupakisha kunembe, futhi iphutha lendawo yalo ngokuyisisekelo lingaphansi kwezinga lemilimitha, ngokunemba okuhle kakhulu.

5. Ukusetshenziswa kwamandla okuphansi: Ngokuvamile amandla e-palletizer engumshini acishe abe ngu-26KW, kuyilapho amandla erobhothi elipakisha azungeze u-5KW, okunciphisa kakhulu izindleko zokusebenza zamakhasimende.

6. Uhlu olubanzi lwezinhlelo zokusebenza: Irobhothi lokupakisha lisetshenziswa kakhulu. Ingakwazi ukuqedela imisebenzi eminingi efana nokubamba, ukuphatha, ukulayisha nokukhipha, nokupakisha.

7. Ukusebenza kahle okuphezulu: Isivinini sokusebenza serobhothi yokupakisha sishesha kakhulu futhi akukho ukuphazamiseka kwesikhathi, ngakho ukusebenza kwayo kahle kuphakeme kakhulu.

8. Izinyathelo ezincane: Irobhothi lokupakisha lingasethwa endaweni ewumngcingo futhi lingasetshenziswa ngokuphumelelayo, elihambisana nokuhlelwa komugqa wokukhiqiza efektri yekhasimende futhi lingashiya indawo enkulu yokugcina impahla.

Namuhla, imboni yokupakisha ingene kancane kancane enkathini ye-automation. Njengomfanekiso oqhudelana kakhulu wobuchwepheshe bokuzenzakalela, amarobhothi ezimboni afaneleka kakhulu ezinqubweni eziphindaphindayo, ezisheshayo, ezinembile neziyingozi. Ukusetshenziswa kwamarobhothi okupakisha akukwazi ukunciphisa izindleko kuphela, kodwa futhi kuletha ukuguquguquka okuphumelelayo. Akukona nje ukupakisha amarobhothi ezimboni, izinkampani eziningi zikhetha ukusebenzisa izinhlobo ezahlukene zamarobhothi ezimboni ngenxa yokuguquguquka nokuthembeka kwawo. Ngokuzayo, amarobhothi ezimboni azothatha indawo yemishini yendabuko eyengeziwe futhi abe ngelinye lamandla okushayela abalulekile ekuthuthukisweni kwemikhakha eyahlukene.

Isikhathi sokuthumela: Nov-20-2024